‘Tiz the season for cold weather flying, and in a few cases, pilots may find the opportunity presents itself to do a few landings on a frozen lake or two!

For pilots from the further north, the question of whether to do this is not a matter of if, it’s just a when each season these landings become a part of normal general aviation operations. Sometimes, the ice is in better condition than the runways! Southern pilots who have never done this may think we are crazy, and those of us that live in the middle zone of the country (I happen to live in Michigan), find that we get lucky enough with the right conditions to be able to do this some years and not others. With that said, under the right conditions, there is no reason it can’t be done safely.

Now, there are a bunch of precautions that I obviously must recommend, but when the conditions are right, it can be a unique and pretty fun way to spend an afternoon of general aviation flying.

First question, is the ice thick enough?

First question, is the ice thick enough?

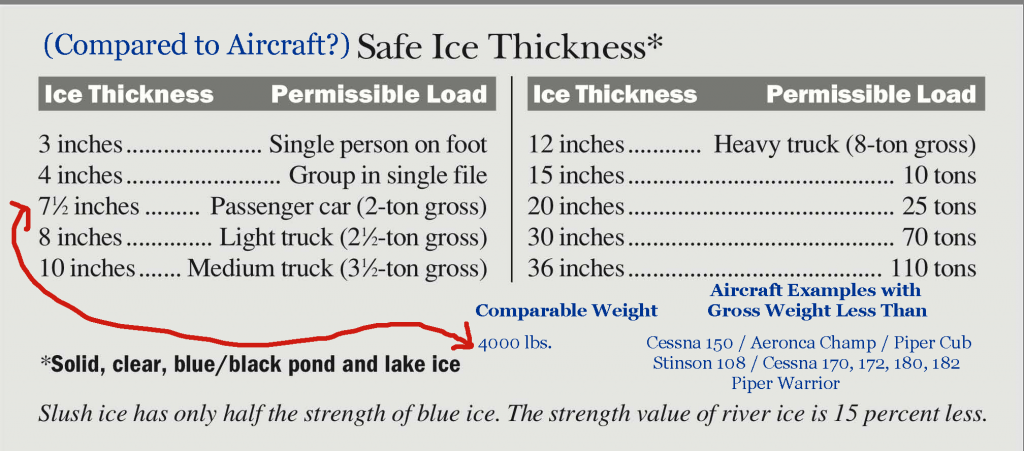

Naturally, no-one wants to sink their aircraft to the bottom of a frozen lake. So, making sure the ice is thick enough, and I mean consistently, is the first task to even start thinking about if you are going to try to make some landings.

There are general rules of ice thickness that can be considered for comparable objects, such as people, vehicles, or other things. If we extrapolate those weights and compare them to some aircraft, we find that for most general aviation aircraft it is a good idea to make sure there is at least 7- 8 inches of ice before considering any landings.